That is not breaking news that freight costs are constantly taking a large slice from the Supply Chain budget of any company that needs to deliver the product to the client. But when the company decides to keep the distributions service in-house, an effective distribution strategy becomes a must. Optimization of the picking, planning of the truck loading and calculation of the distribution routes are the major steps in the logistic process.

To avoid significant unexpected expenses along the way of the transportation chain, the planning should be backed up by technology. This is why the leading manufacturer of the enclosure materials with steel wires in Spain decided to innovate the whole process by the developing and implementing a tailored AI solution. The solution that would unite two paired yet separate processes and reduce the lead time and transport costs.

Aquiles Solutions became the technological partner in the project of the “Optimization of the truck loading and distribution routes”, providing the analysis and deployment of the tool based on the AI algorithm. But a preliminary analysis put into the light the need to take one step backward and start the whole process with optimizing the picking!

Simultaneous planning of truck loading and distribution routes

Previously, this task was solved manually trying to maintain a balance between truck loading and calculating delivery routes. The whole information was maintained in one major Excel file with direct connection with the ERP system of the client, which made it impossible to make life updates.

Due to the nature of the products (vastly diversified in shapes and packaging) and the complexity of the calculations, the pallets were assembled on the eve of departure day, making the planning extremely “short-sighted” and rigid for occurring changes.

The optimization of these two processes would allow:

- Automatically read data of all orders and their characteristics. The tool will be connected to the ERP on constant basis and updat itself to any changes.

- Automatically define product boxes, especially the contents and shape of them.

- Automatically calculate the distribution of boxes in trucks.

- Report the loading process, describing the loading process with simple and clear instructions.

- Calculate the optimal distribution routes.

- Improve global optimization, through the creation of delivery boxes, their distribution in trucks and their delivery routes.

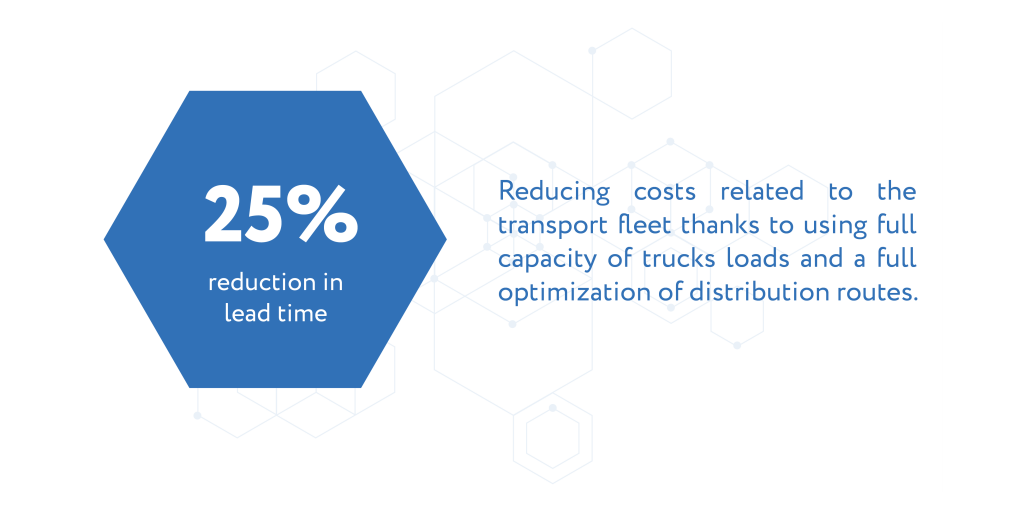

By combining integer linear programming methods with heuristic methods, the complex simultaneous calculations were done now just in a matter of minutes whenever it was needed. This allowed the client not only to plan the capacity of the transport fleet up to 10 working days, but also to adjust easily to constant changes.

Download the success story to learn more about how the AI-based tool solves the optimization dilemma: “Do I first optimize the truck loading or distribution routes”? Download the success story to see what real, tangible benefits this solution brings to the company like yours.

Benefits of truck loading optimization

A smart transportation planning is vital to avoid unnecessary expenses. And customised digital solutions based on the Artificial Intelligence prove to be the best ally for the manufacturing and logistics companies that are in need of the planning and automating processes that involve picking, loading and delivery of the goods. These solutions revolutionize the whole processes bringing significant savings to the companies and strong competition advantage.